C & C Construction Management, Inc. 10063 Sandmeyer Lane Philadelphia, PA 19116 (215) 673-1799 www.cccmgmt.com

Contact:

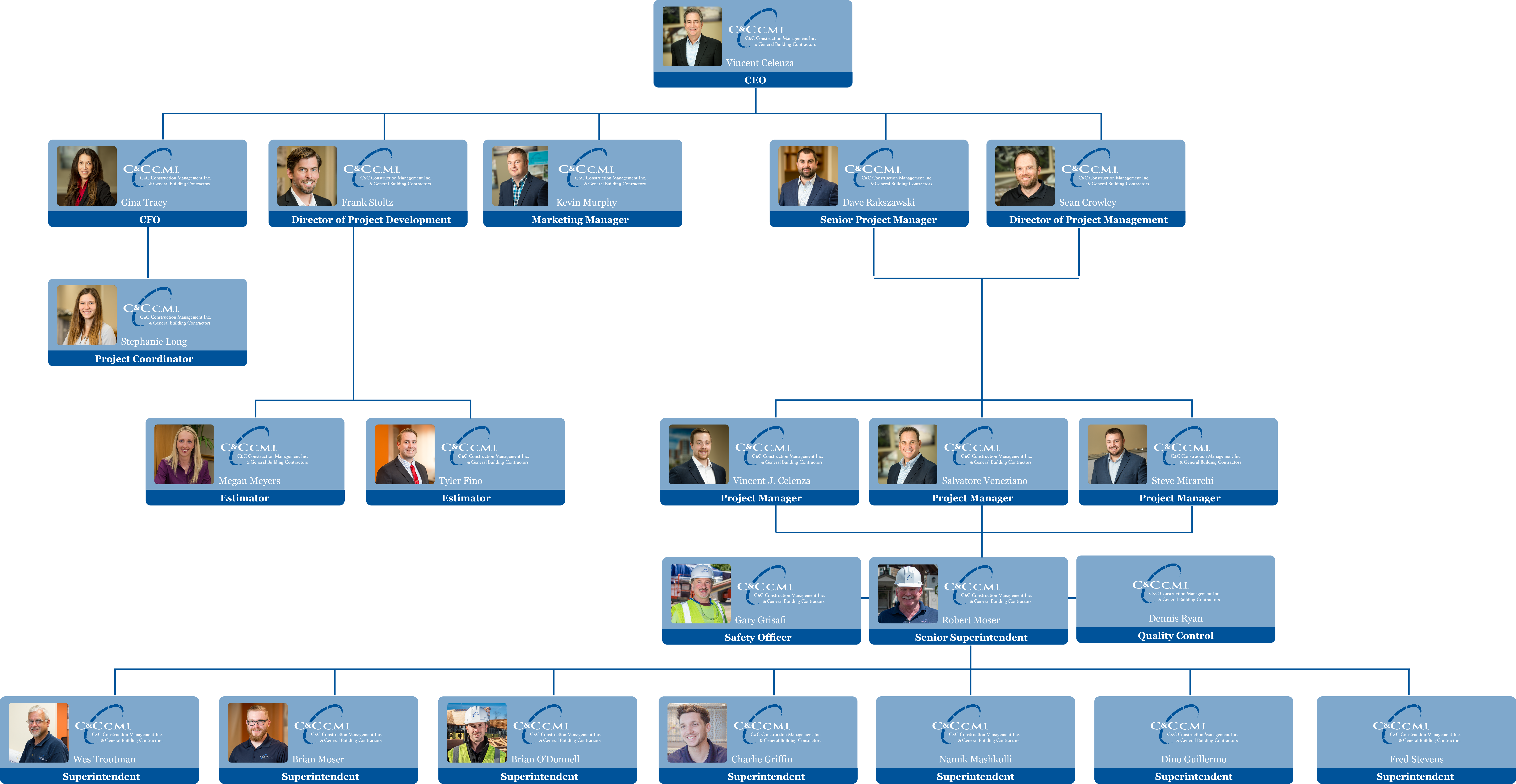

Vince Celenza – President & CEO Frank Stoltz – Senior Estimator FStoltz@cccmgmt.com

We have a sound financial base which include banking relationships with: Santander Bank, Citizens Bank, First Trust, Provident Bank of NJ and TD Bank

Surety Company: Ohio Casualty Company Bonding capacity for a single project: $80,000,000 Agent: Rosenberg & Parker 455 S. Gulph Road, Suite 400, King of Prussia, PA 19406 Contact: Christine Hrusovsky (610) 667-5200

Mission Statement

Princeton Community Village Apartments

Ground Breaking October 2021

Similar Apartment Building Projects

The Atrium At Red Bank

Red Bank, NJ

14-Story Mid-rise Luxury Apartments

Owner’s Rep: : Gary Puma

Phone Number: : (609) 947-0419

Architect: DI Group, Vincent Myers (609) 865-5172

Stafford By The Bay

Manahawkin, NJ

New 72,000 SF 3-Story Apartment Complex

Owner’s Rep: : Ed Truscelli

Phone Number: : (609) 924-3822

Architect: DI Group, Vincent Myers (609) 865-5172

The Oaks At Tom River Apartments

Whiting, NJ

New 74,000 SF 3-Story 85 Unit Apartment Complex

Owner’s Rep: Gary Puma

Phone Number: (609) 947-0419

Architect: Perez + Radosti Associates, P.C., Mr. Ric Perez

Safety

C&C’s Safety Record:

Experience Modification Factor is 0.8950.

C&C makes safety a top priority and establishes a “safe culture” on every jobsite. At the beginning of each new project, it is mandatory that all subcontractors submit their safety manual to our office before work commences. Our team in field continues with our safety efforts each day by conducting toolbox talks, reiterating site-specific hazards and the required work practices necessary to maintain a safe working environment for everyone; all contractors are required to attend these safety meetings. In addition to these safety meetings, our safety officer, Gary Grisafi visits every jobsite on a bi-weekly basis to ensure that all personnel on-site are in compliance with the latest OSHA requirements and safety regulations. He performs tool and equipment inspections and confirms that every team member and subcontractor has received the proper training PPE, fall protection and are attending the daily toolbox talks.Quality Control

C & C’s quality management system includes comprehensive operating procedures, checklists, and proper employee training to ensure an outstanding final product. Our quality assurance officers meet with onsite superintendents regularly to ensure that company expectations are met throughout all stages of construction, rough, prior to sheetrock, closing up ceilings, all finishes etc. We utilize 360 cameras that are integrated with our Procore platform to identify flaws that need correction. The QC team sends an alert via procore to the responsible subcontractor so there is no confusion, once the item is corrected the QC team does a final walk through. We’ve found that this QC phase minimize any architect/owners punch list. Throughout the project our in house project coordinator gathers all necessary product information, Flame Spread Data, warrantees, cleaning instruction, MSDS, as builts, etc for when the building is complete a digital copy of all close out documentation is ready when the building is occupied. Our team members and our subcontractors understand our commitment to quality and never accept “good enough.” Our stringent quality control results in expedited turnover to the owner.Green Construction Experience

The C&C project team has been engaged in many projects involving sustainable features and energy efficient design including Green Enterprise, Energy Star, LEED, and Green Futures. We continually strive to keep abreast of current sustainability trends through seminars, training, and on-line courses.

One of our completed projects, Robert Noble Manor, was constructed utilizing many Green Elements. This project complied with the requirements of the Green Futures program and was built using the modular construction approach, which further enhanced the sustainability of the project. C&C worked closely with the design team assisting in the selection of materials, means, methods, and equipment to exceed the sustainability goals while maintaining the budget. Some of the items featured on this project are Low VOC products, Non-vinyl flooring, Energy Star appliances, high MERV air filters, low flow plumbing fixtures, energy efficient lighting, and an in-house recycling center with a program for each resident unit. Upon completion of the project, 3rd Party Green Future Certified Engineers commissioned the building and performed the required field testing such as blower door tests to ensure the facility performed per the stated design requirements

In addition to completing projects with Green Elements, C&C has implemented strategies to support sustainable practices such as a company-wide recycling program at our offices and on our job sites by utilizing comingled or single stream dumpsters to divert waste from landfills. We have also renovated our offices to incorporate LED lights, Energy Star appliances, and low flow plumbing fixtures.

C&C utilizes local suppliers and manufacturers whenever possible to not only reduce the carbon footprint of materials used on our projects, but to also support the local economies. A few examples are utilizing local Millwork Vendors, purchasing flooring from Floorfolio, who manufacturers their products in New Jersey, and working with lighting consultants to use light fixtures manufactured in New Jersey, Massachusetts, and other areas in the United States.

PRE-CONSTRUCTION SERVICES

Design Development Phase

During this phase C&C will work with the project team to evaluate the project and produce design

development documents for pricing. We have assumed attendance at Bi-weekly or Monthly Design

Meetings with the project team to keep connected and abreast of any issues or design decisions. We will schedule additional site visits to evaluate the existing conditions and perform exploratory work as required to evaluate existing conditions and limit unforeseen challenges.

C&C will also review progress drawings for any constructability issues and or conflicts and hold separate Design Coordination Meetings with selective subcontractors if needed. In addition we will use our in-house Construction Review Document Checklist that we have developed through the years working on countless senior living projects. C&C will collaborate with the Project Team to bring maximum value and efficiency to the Frederick Living Phase 1 Project and specifically target the following areas. Upon the completion of Design Development documents C&C will prepare the following:

- Itemized estimate based on typical unit/building layouts with selective subcontractor input

- Value Engineering Analysis and Recomendations

- Preliminary Project Schedules and Logistics Plans